In professional packaging environments, materials are selected not for attention, but for alignment with established processes. Tyvek Header Bag from Hopeway AMD is often mentioned in conversations focused on orderly sterilization and storage practices. Its design reflects a practical approach to combining breathable material with a structured header, supporting workflows where consistency and clarity are expected.

Header bags are commonly used in medical, laboratory, and technical fields that rely on standardized handling procedures. The added header section allows for organized presentation, labeling, or hanging, which can support inventory control and visual management. This structure helps teams maintain orderly storage areas while keeping packaged contents protected before use.

Breathability is another reason such bags remain relevant. During sterilization, controlled airflow is necessary to allow sterilizing agents to reach the contents effectively. After processing, the same material supports a protective barrier during transport and storage. This dual function makes header bags a familiar option in facilities that manage both sterilization and distribution under one system.

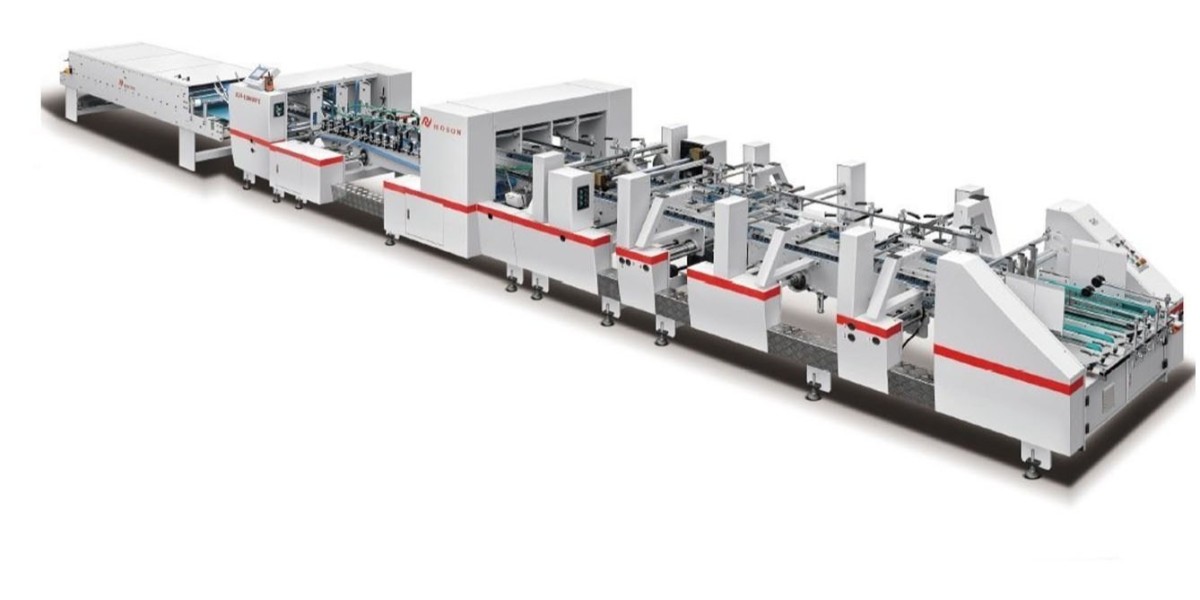

From a usability standpoint, packaging solutions must integrate smoothly into daily routines. Header bags are often selected because they can be sealed using common equipment and handled without complex steps. Predictable behavior during sealing and opening helps reduce interruptions, especially in environments where time and attention are divided among many tasks.

Visibility and identification also play an important role. Clear sections of the bag allow staff to recognize contents quickly, supporting organized workflows and reducing unnecessary handling. When instruments or components can be identified at a glance, teams are better positioned to maintain clean and efficient operations.

Compliance considerations influence nearly every packaging decision in regulated industries. Materials must align with internal procedures and external guidelines, and packaging formats should support validation and documentation efforts. Header bags are often incorporated into these systems because their design is straightforward and compatible with existing protocols.

Sustainability discussions continue to shape supply chain decisions across healthcare and technical sectors. While safety remains the priority, organizations also look at material efficiency and waste reduction. Packaging that supports proper sizing and minimizes excess layers can contribute to more responsible use without altering core processes.

As workflows evolve and facilities adapt to new demands, packaging solutions that balance familiarity with functionality tend to remain in use. Header bags continue to be evaluated not as trends, but as practical tools that support daily operations across multiple settings.

If you are considering how breathable packaging fits into your own processes, it may be worth taking a closer look beyond surface descriptions. Visiting https://www.hopewayamd.com/news/industry-news/tyvek-header-bag-balancing-durability-and-sterilization-permeability.html could offer perspectives that quietly connect materials, workflow needs, and real-world application, inviting you to explore further at your own pace.