Modern manufacturing workshops are constantly looking for ways to improve precision and reduce downtime, which is why many buyers turn to an Axis Milling Machine. Instead of focusing solely on specifications, most factories want to understand how the machine performs in real daily operations and whether it integrates smoothly into existing workflows.

An Axis Milling Machine is designed for multi-directional machining, allowing operators to work on complex geometries without repeated repositioning. This capability directly influences production efficiency. Operators can complete multiple cuts or surface finishes in a single setup, which reduces handling time and keeps workflow predictable, especially for high-precision industries like automotive or aerospace.

Buyers often want to know how the machine interacts with different milling cutters. An Axis Milling Machine can accommodate a variety of cutters, from end mills to face mills, depending on the task. The choice of cutter affects surface finish, cycle time, and tool wear. Engaging directly with an Axis Milling Machine Factory allows buyers to select compatible cutters and setups that match both part requirements and shop practices.

Ease of use is another key concern. A machine with complicated controls can slow production rather than help it. Modern Axis Milling Machine designs focus on intuitive interfaces, allowing operators to set parameters quickly and monitor machining progress. This approach ensures consistent output even when new operators are training on the line.

Adaptability is often a deciding factor for factories with diverse production needs. An Axis Milling Machine can adjust to different part sizes and material types. Manufacturers that provide customization options, like tooling guides or fixture setups, allow factories to expand their capabilities without needing multiple machines. This flexibility is especially valuable for workshops producing small-batch or prototype orders.

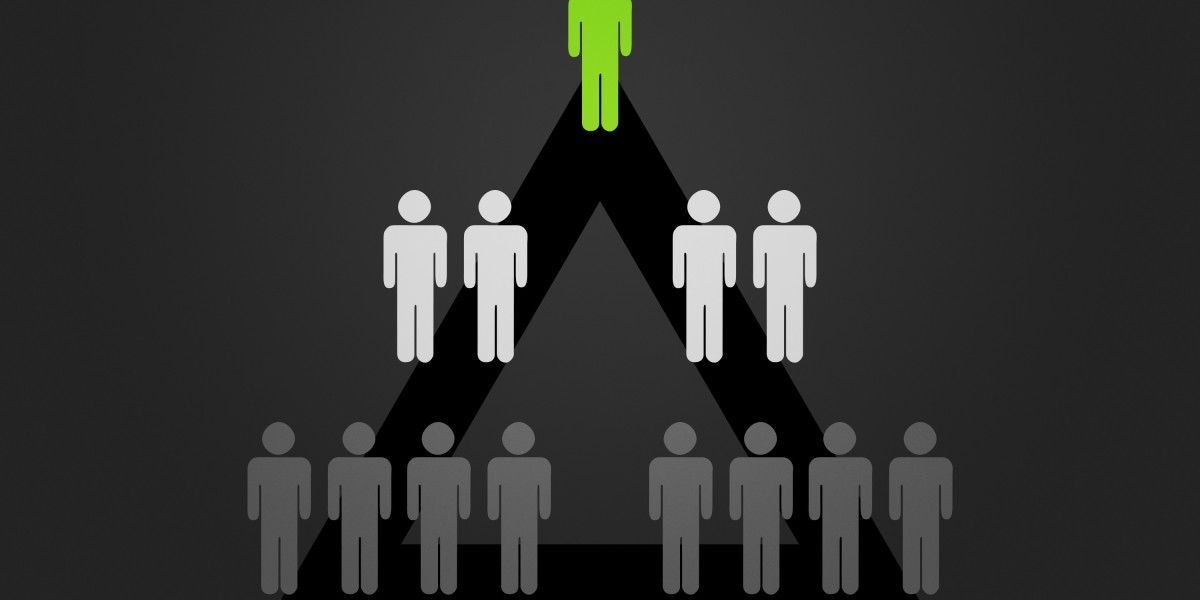

Here are several angles factories typically explore when evaluating an Axis Milling Machine:

Precision and Surface Finish

Accurate machining ensures parts meet strict tolerances, reducing post-processing work.

Production Efficiency

Multi-axis capabilities streamline workflows and reduce handling time.

Tooling Flexibility

Compatibility with various cutters allows one machine to serve multiple applications.

Supplier Support

An experienced Axis Milling Machine Factory guides setup, maintenance, and customization.

Durability and maintenance also influence purchasing decisions. An Axis Milling Machine is built to withstand continuous operation with minimal intervention, reducing unexpected downtime. For sourcing teams, this reliability translates to predictable planning for production schedules and fewer disruptions, which is critical for meeting client deadlines.