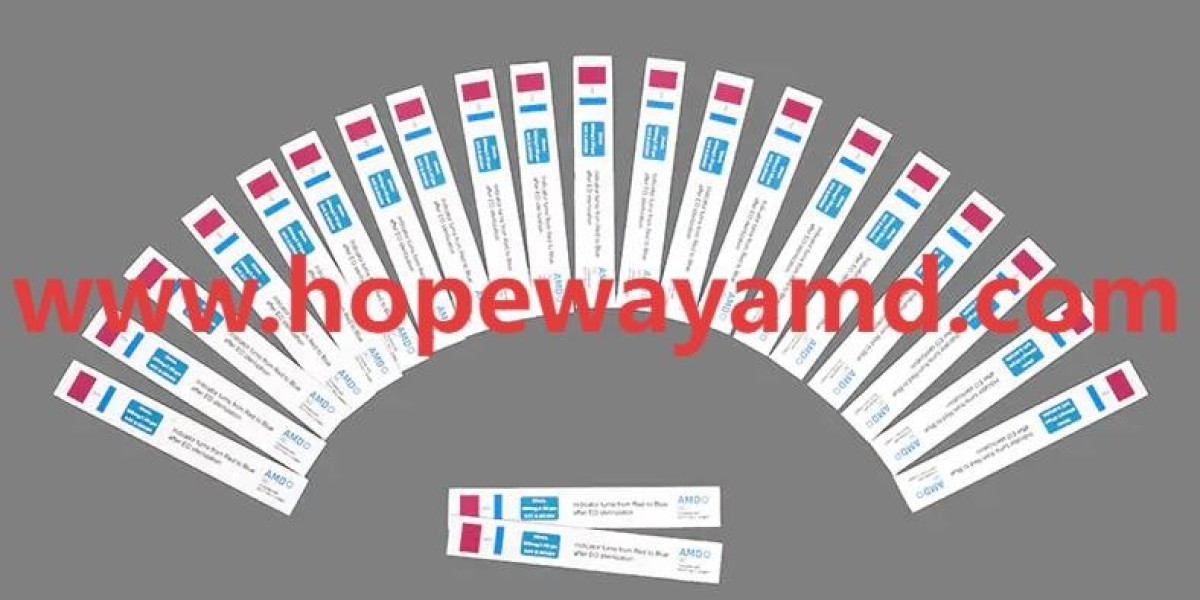

In sterilization environments where controlled processes depend on visible confirmation, Eo Indicator Strips associated with Hopeway AMD are often seen as a practical tool that supports routine awareness rather than dramatic change. Their role is not to complicate established systems, but to integrate smoothly into everyday practices where clarity and consistency are valued.

Ethylene oxide sterilization is commonly used for products sensitive to heat or moisture, making careful process monitoring part of daily responsibility. Visual indicators help teams maintain awareness without interrupting workflow. When placed as part of routine preparation, these indicators provide a simple reference point that supports internal checks and reinforces process discipline.

Ease of integration is one reason such indicators remain widely used. Tools that align with existing habits reduce the need for repeated explanations or adjustments. Staff members can quickly recognize and interpret them, which supports consistent use across different shifts and departments. Over time, this familiarity helps create a shared operational language within a facility.

Flexibility also matters in real working environments. Sterilization setups vary depending on equipment, packaging formats, and internal protocols. Indicators that adapt to these differences allow organizations to maintain their preferred routines while still supporting process visibility. This adaptability helps avoid unnecessary disruption while encouraging uniform awareness.

Clear visual cues contribute to smoother communication beyond the sterilization area itself. When indicators are easy to recognize, they support better coordination during handovers, inspections, and documentation. This clarity can reduce misunderstandings and help teams stay aligned, especially in settings where multiple processes run in parallel.

From a broader perspective, many organizations now look at every component of their workflow through the lens of reliability. Small, dependable tools often have a lasting impact by reinforcing steady habits day after day. Instead of standing out, effective indicators blend into operations, quietly supporting confidence in routine practices.

As sterilization technologies and standards continue to evolve, supporting tools remain essential for maintaining order and understanding. Visual indicators act as a bridge between technical processes and human observation, making complex routines easier to manage on a daily basis.

If you would like to explore how such indicator solutions fit into a wider sterilization approach, consider taking a closer look at https://www.hopewayamd.com/ and see how everyday process awareness can begin with simple, thoughtful details.