Growing expectations for smarter, cleaner, and more productive cap manufacturing processes have pushed many factories to upgrade their equipment, especially as global brands require higher levels of accuracy and reliability, leading to a surge in interest in advanced systems where the Cap Compression Machine supports precise molding conditions for large-scale operations. As packaging trends continue evolving, manufacturers are discovering that the Cap Compression Machine aligns well with the shift toward lightweight, cost-efficient, and environmentally responsible closures. This transition has motivated companies like Taizhou Chuangzhen Machinery Manufacturing to develop solutions that address the complexities of modern cap production.

The current market environment emphasizes efficiency, flexibility, and minimized waste. Beverage and consumer goods industries are expanding rapidly, with new product formats emerging across bottled water, functional beverages, household detergents, and personal care items. This diversity demands cap production systems capable of handling varying geometries and design features without sacrificing consistency. Manufacturers also face pressure to lower total operating costs, reduce defect rates, and ensure steady output even during extended production cycles. As competition intensifies, the ability to meet these operational goals becomes a decisive factor for long-term profitability and equipment selection.

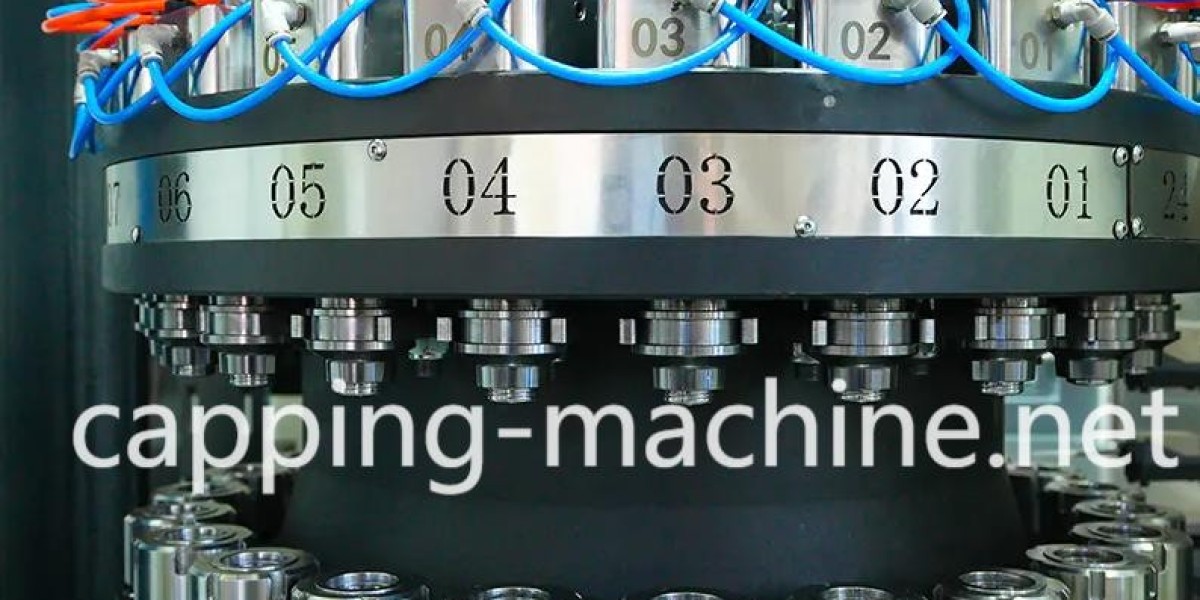

Technological innovation plays a crucial role in meeting these new market demands. Modern compression molding systems incorporate advanced control algorithms, digital monitoring platforms, and accurate thermal management structures. These capabilities enable operators to maintain stable temperatures, dial in precise timing, and achieve uniform material distribution throughout the molding process. Improved mechanical components contribute to smoother motion, reduced vibration, and longer component life. Taizhou Chuangzhen Machinery Manufacturing integrates these engineering enhancements into its equipment to help customers maintain stable, predictable performance across high-speed cap production environments.

Energy-saving improvements continue to influence the direction of molding equipment design. Compression molding is naturally energy efficient because it processes plastic at lower melt temperatures, and new system enhancements further strengthen this advantage. Heat insulation materials reduce energy loss, while intelligent cooling channels regulate temperature more effectively across continuous cycles. The cumulative effect is a significant reduction in electricity usage without compromising product quality. For manufacturers focused on lowering carbon emissions and operational costs, these features offer meaningful long-term value and help meet increasingly strict sustainability requirements across global markets.

The application range of compression-molded caps continues expanding due to the versatility and strong sealing performance they provide. Beverage brands rely on them to maintain carbonation levels and protect product freshness, while personal care and health product manufacturers require caps that combine aesthetic appeal with structural reliability. Industrial chemical packaging demands closures that must resist pressure fluctuations, liquid leakage, and chemical interaction. Compression molding supports these needs with stable material flow and controlled molding environments, enabling manufacturers to meet diverse performance standards using a single, adaptable production system.

Performance advantages of compression-molded caps remain a defining reason behind growing industry adoption. The process distributes material evenly across the cap structure, minimizing internal stress and ensuring uniform strength. This is particularly important for closures used in fast-moving production lines where even minor inconsistencies can cause sealing failures or machine jams. The absence of gate marks contributes to cleaner surfaces and better compatibility with automated application systems. Material preservation is also improved due to reduced thermal degradation, allowing manufacturers to maintain product purity and mechanical stability across large production batches.

As industries continue modernizing their production capabilities, the demand for equipment suppliers capable of providing durable engineering and responsive technical support has increased significantly. Taizhou Chuangzhen Machinery Manufacturing has positioned itself as a dependable partner by focusing on high-performance designs, stable mechanical structures, and continuous refinement of operational features. Its solutions enable manufacturers to maintain efficient, reliable cap production while adapting to rapidly changing market requirements. More information about available equipment and technologies can be found at https://www.capping-machine.net .