As global packaging standards rise and manufacturers seek cost-effective solutions, many businesses are evaluating the Cap Compression Molding Machine Price to understand the balance between initial investment and long-term efficiency, particularly since the Cap Compression Molding Machine Price often reflects not only equipment quality but also energy-saving technologies, precision control systems, and reliability. Taizhou Chuangzhen Machinery Manufacturing has developed advanced machines designed to provide stable output, high-speed operation, and minimized energy consumption for a variety of industries, including beverage, personal care, and chemical packaging.

Market demand for caps has grown significantly due to expanding beverage production, household chemicals, and cosmetic products. Consumers expect closures that are lightweight, visually consistent, and capable of maintaining integrity under pressure or chemical exposure. To meet these needs, manufacturers require machinery that can handle multiple cap sizes and designs without compromising speed or quality. Choosing a Cap Compression Molding Machine requires consideration of both short-term costs and long-term operational benefits, including energy efficiency, material savings, and reduced defect rates, making modern systems a critical investment.

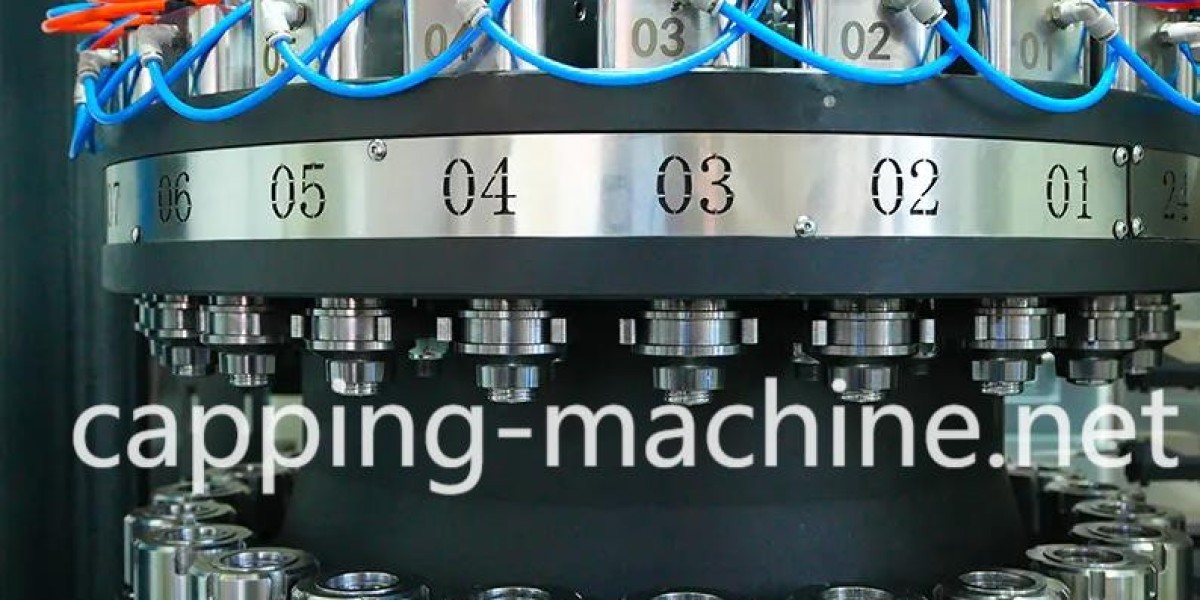

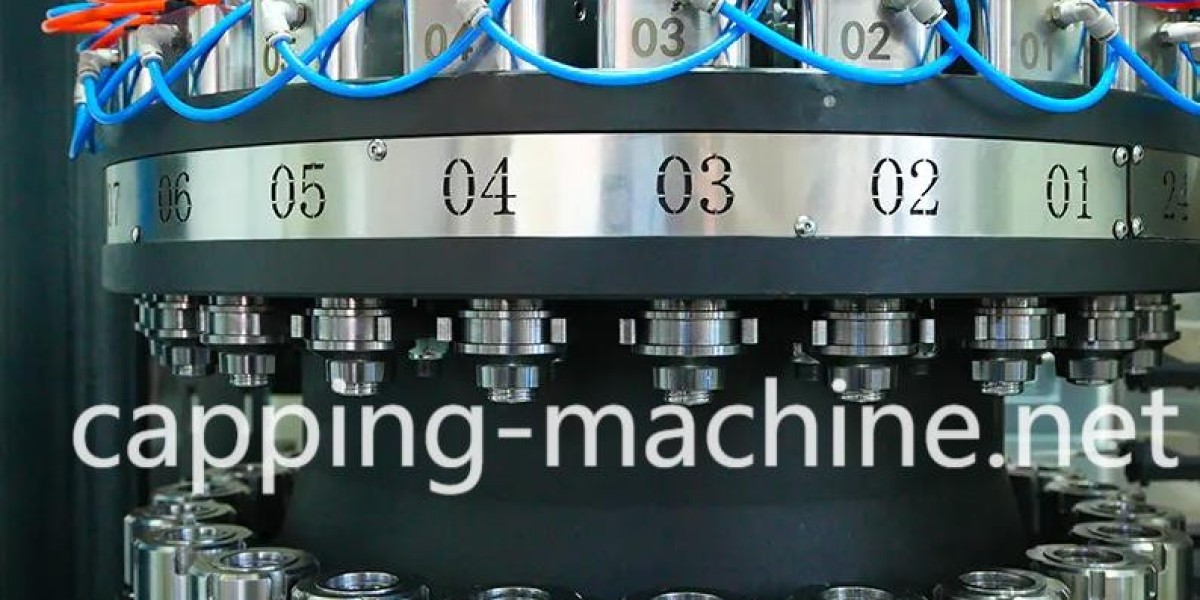

Technological innovation continues to redefine cap manufacturing processes. Modern compression molding machines integrate digital monitoring systems that track temperature, pressure, and cycle time, ensuring uniform material distribution and consistent wall thickness. Servo-driven mechanical components enable precise movements and reduce mechanical wear, while automated thermal regulation enhances process stability. Taizhou Chuangzhen Machinery Manufacturing incorporates these features into its machines to improve reliability, reduce downtime, and provide operators with enhanced control over production parameters, ensuring high-quality caps throughout extended runs.

Energy efficiency has become a central factor influencing purchasing decisions and the evaluation of Cap Compression Molding Machine Price. Compression molding inherently consumes less energy than injection molding, thanks to lower melt temperatures and efficient thermal transfer. Advanced systems further improve efficiency through insulated heating elements, optimized cooling channels, and smart energy management. Factories benefit from reduced electricity usage, lower operating costs, and minimized environmental impact, aligning with global trends toward sustainable manufacturing practices.

Applications for compression-molded caps are extensive and varied. Beverage companies rely on closures that maintain carbonation and prevent leakage, while personal care and cosmetic products require caps that are both functional and visually appealing. Industrial and household chemical manufacturers demand caps that resist deformation, maintain structural integrity, and prevent spillage. The Cap Compression Molding Machine produces closures with even material distribution, reduced internal stress, and precise dimensions, meeting diverse performance requirements across these sectors.

Performance advantages of compression-molded closures are significant. Caps produced with these machines feature smooth surfaces, uniform wall thickness, and minimal internal stress, reducing defects during bottling, transport, and storage. The lower processing temperature preserves material properties, enhancing elasticity, chemical resistance, and durability. Reliable machines reduce production interruptions, lower maintenance costs, and ensure consistent output across long production cycles, helping manufacturers maximize return on investment.

As companies seek to modernize their packaging lines, partnering with an experienced equipment provider is essential. Taizhou Chuangzhen Machinery Manufacturing delivers Cap Compression Molding Machines with durable construction, energy-efficient features, and precise process control to support high-volume, high-quality cap production. For further details on specifications and product offerings, visit https://www.capping-machine.net .