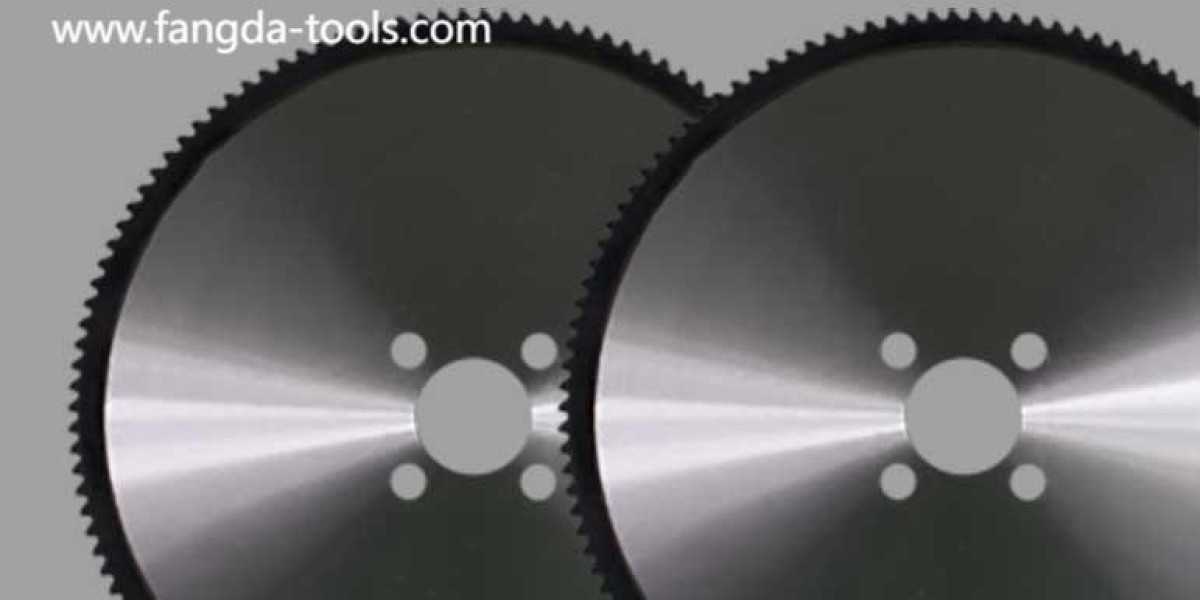

Selecting a cutting tool often begins with assessing its stability, geometry, and adaptability across various materials. A TCT Circular Saw Blade from fangda-tools is frequently chosen by users seeking steady, predictable cutting performance that aligns with both routine and specialized tasks. Saw blades influence the accuracy of each cut, the finish of the workpiece, and the overall efficiency of the process, making the initial choice an important factor in project planning.

Effective cutting depends on the relationship between tooth structure and material properties. When teeth are arranged with consistent spacing and controlled angles, they help manage chip flow and reduce unnecessary resistance. This contributes to smoother cutting paths and supports more uniform results across wood, composite materials, and certain lightweight metals. A stable body plate further enhances this process by maintaining alignment during operation, reducing vibration, and supporting straight-line accuracy.

Users also consider the blade's ability to support different feed rates and cutting depths. A blade designed with balanced weight distribution allows operators to maintain control during both slow, deliberate cuts and faster passes. This flexibility is useful in workshops, installation tasks, and fabrication environments where material thickness and density vary from one step to the next.

Maintenance is another influential factor for long-term performance. A blade that retains its structure through extended use, responds well to cleaning, and supports routine sharpening helps minimize downtime. For professionals, this translates into consistent scheduling, predictable output, and fewer interruptions caused by tool degradation. For home users and DIY practitioners, it provides confidence that each project can proceed with sustained clarity and precision.

In many cases, tool selection also reflects the balance between control and convenience. A blade compatible with standard equipment reduces the need for repeated adjustments and supports quick transitions between tasks. Smooth engagement with the workpiece allows operators to focus on guiding the tool rather than compensating for irregular motion or excessive noise. This contributes to safer and more manageable working conditions, whether on a fixed workstation or mobile cutting setup.

Given the role saw blades play in shaping material edges, creating structural joints, and preparing surfaces for further assembly, the choice of blade can directly affect downstream processes. Users benefit from blades that support predictable kerf width, controlled heat generation, and consistent cutting rhythm, all of which influence the accuracy and durability of the final construction.

If you are considering options for reliable and steady cutting performance, you may find value in reviewing blade selections designed with practical workmanship in mind. Instead of browsing generically, take a focused step toward tools aligned with project-ready functionality. Begin that review by visiting https://www.fangda-tools.com/ and engage with options that may refine your next cutting process.