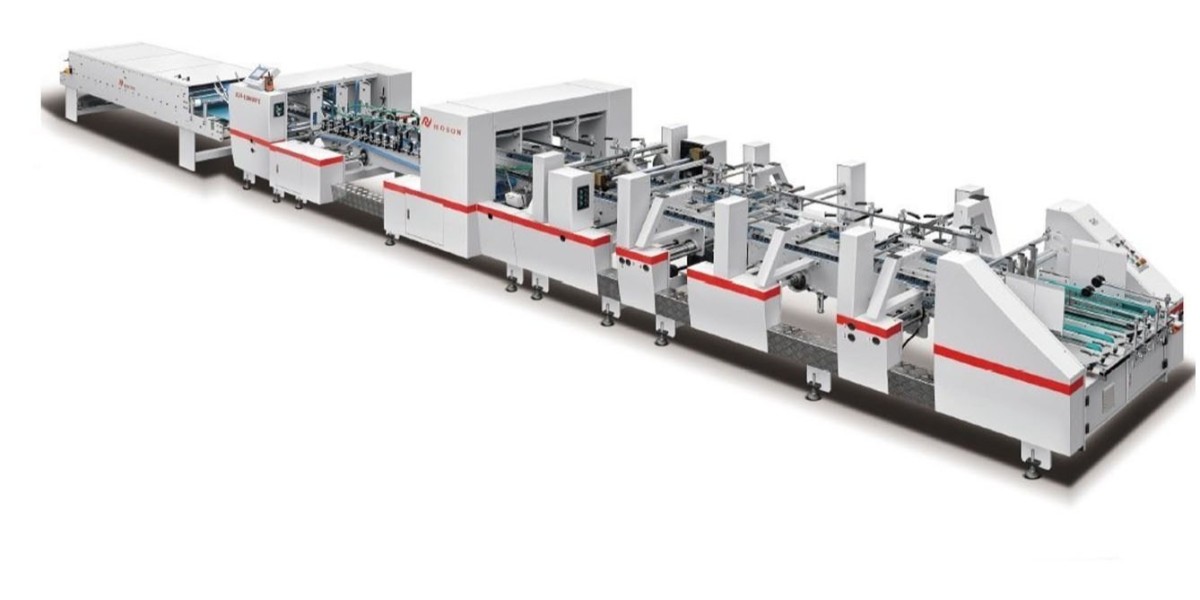

An Auto Folder Gluer Machine stands out as the ideal solution for packaging producers who want to transform manual folding and gluing into a seamless, high‑performance workflow. In an era where demand fluctuates and orders often arrive in bulk, relying on human labor alone risks inconsistency, slow turnaround, and rising costs. With such a machine from cenwan, a packaging line becomes faster, more reliable, and more efficient — giving manufacturers the edge they need for modern production demands.

Imagine flat carton blanks coming off a die‑cut line, fed smoothly into a machine that auto‑feeds, folds along crease lines, applies glue with precision, and presses each carton into its final shape — all without constant supervision. From straight‑line cartons to crash‑lock bottoms and complex multi‑panel boxes, the machine handles variety without compromising speed. The result: fully assembled boxes emerge continuously, ready for packing or shipping. This kind of automation converts what was once repetitive labor into a streamlined, stable process.

One of the greatest advantages lies in consistency. Manual folding and gluing are subject to human error — misaligned folds, uneven glue application, weak adhesion — especially across large volumes or long shifts. Automation removes those variables. Every fold is exact, every glue line uniform, and every box meets quality standards. For clients demanding reliability, that consistency can make the difference between satisfied orders and costly returns.

Beyond uniformity, an auto folder gluer dramatically reduces labor dependency. A handful of workers overseeing a machine can replace many manual operators. Training becomes simpler, fatigue and human‑error risk disappear, and the workforce becomes more agile. For packaging businesses in markets with rising labor costs or staff shortages, this shift translates into real savings and operational stability.

Material efficiency is another significant benefit. Because glue is applied precisely — only where needed — waste is minimized. Misfolded or poorly glued cartons become rare, lowering the rate of rejects and saving both raw material and labor associated with rework. Over time, reduced material loss and fewer defects contribute to lower per‑unit costs and improved profitability.

Flexibility is also essential in today’s fast‑changing market. A versatile machine adapts to different carton sizes, styles, and material thicknesses. That makes it easier to switch production runs when orders change, without requiring different machines or extensive manual adjustment. For businesses offering a wide range of box formats — from simple shipping cartons to delicate retail packaging — this adaptability is invaluable.

Moreover, modern auto folder gluers often integrate with upstream and downstream systems — feeding from die-cutters or printers, then linking to packing or sealing lines — forming a complete automated production chain. This integration reduces manual transfer errors, increases throughput, and supports a more organized, scalable production environment. For companies looking to grow or scale quickly, such automation becomes a foundational investment.

For manufacturing operations seeking reliable, efficient, and flexible carton production, an Auto Folder Gluer Machine from cenwan offers a clear path forward. It delivers speed without sacrificing quality, reduces labor reliance, cuts waste, and adapts to varied packaging needs. If you want to elevate your packaging line’s productivity and reliability while maintaining cost effectiveness, explore what cenwan provides — quality machines built for modern packaging demands. Visit our website to learn more about how this automation solution can upgrade your production workflow https://www.cenwanmachine.com .