Growing investment in large-scale cap production has made manufacturers increasingly attentive to the relationship between equipment capability and long-term economic return, particularly as the Cap Compression Moulding Machine Price often influences early planning for facility upgrades. While cost is a starting consideration, global producers in food, beverage, pharmaceuticals, and consumer goods are now emphasizing how machinery performance, energy optimization, and production flexibility can determine overall competitiveness. In this evolving environment, Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. has focused on engineering systems that align with shifting expectations and expanding market needs.

Increasing Demand Driven by Packaging Diversity

Rapid changes in global consumption habits have increased the demand for packaging closures that combine functionality with visual appeal. Brands expanding into flavored beverages, health-oriented drinks, and specialized household chemicals require caps with distinct structural and aesthetic features. As manufacturers diversify their product lines, the operational demands placed on molding machinery have intensified.

Factories now operate in shorter planning cycles and handle more SKU variations than ever before. They must adapt quickly to produce caps with different diameters, closure types, color requirements, and torque behaviors. Chuangzhen’s equipment responds to this trend by offering systems designed for high-precision operations that maintain performance continuity during production transitions. The company’s understanding of market momentum ensures that its machines support manufacturers who must deliver both volume and variation to stay competitive.

Energy-Saving Mechanisms That Reduce Long-Term Operating Costs

Energy use and overall efficiency remain essential considerations for plants operating multiple lines simultaneously. Many regions face rising electricity prices and stricter eco-regulations, pushing manufacturers to look for equipment that reduces power consumption without compromising output. Compression molding technology already provides structural advantages by consuming less energy in resin plasticization, but modern machinery enhances these benefits through targeted innovations.

Chuangzhen’s engineering teams focus on optimizing heat distribution, stabilizing melt flow, and reducing mechanical resistance within moving components. These improvements minimize thermal loss, reduce cycle-to-cycle energy variation, and maintain consistent cavity temperatures. As a result, factories benefit from smoother operations and more predictable consumption patterns. Lower energy expenditure across thousands of cycles significantly improves overall production economics, making energy efficiency a core advantage rather than an optional feature.

Expanding Application Scenarios Across Multiple Industries

The versatility of compression-molded caps has enabled them to be used across a broad range of industries. Beverage companies rely on caps designed to maintain carbonation stability. Edible oil producers prioritize controlled dispensing and durability in shipping environments. Pharma and healthcare industries require reliable sealing integrity and precise dimensional consistency.

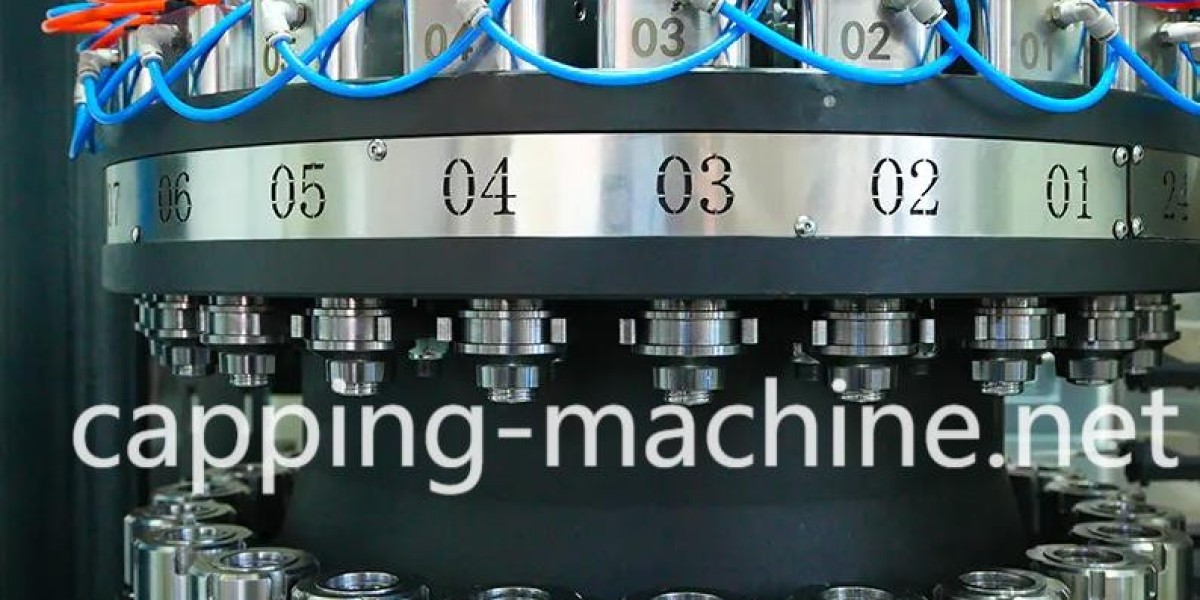

Chuangzhen’s systems are engineered to serve these diverse fields with minimal adjustments. Their mechanical structure supports stable resin metering, uniform temperature control, and precise cavity rotation—essential factors for producing caps that meet stringent industry standards. Whether the requirement is for lightweight water bottle closures or high-torque detergent caps, the machines deliver dependable molding performance tailored to specific product needs. This adaptability is increasingly valuable for factories aiming to serve global customers whose standards may vary across regions.

Performance Advantages That Enhance Product Value

One of the most significant advantages of modern compression molding equipment is its ability to maintain long-term production stability. Consistent melt distribution, predictable mold temperature, and accurate cavity pressure stabilize the physical properties of each cap. Manufacturers benefit from improved sealing performance, smoother surface finishes, and superior dimensional consistency.

Chuangzhen integrates these performance goals into every stage of machine development. The equipment features reinforced structural stability, high-precision servo systems, and optimized cooling channels that help reduce cycle deviations. These enhancements lower scrap rates, cut maintenance intervals, and improve overall equipment utilization. By maintaining consistent mechanical output across extended production periods, factories can maximize efficiency while ensuring product quality remains uniform.

Building Global Partnerships With High-Quality Production Solutions

As the packaging industry becomes increasingly global, manufacturers seek partners that offer not only advanced machinery but also reliable support and long-term engineering insight. Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. continues to strengthen its reputation as a dependable provider by delivering machines that integrate seamlessly into modern production lines. Their equipment is engineered for durability, stability, and operational efficiency—qualities that matter to high-output manufacturing environments. More information about their molding solutions can be found at: https://www.capping-machine.net/product .