Gusu Chocolate Ball Mill Manufacturer plays a central role in shaping buyer expectations regarding chocolate production efficiency, product consistency, and operational support. For manufacturers, providing reliable equipment and clear guidance is critical for enabling factories to meet production goals while maintaining chocolate quality.

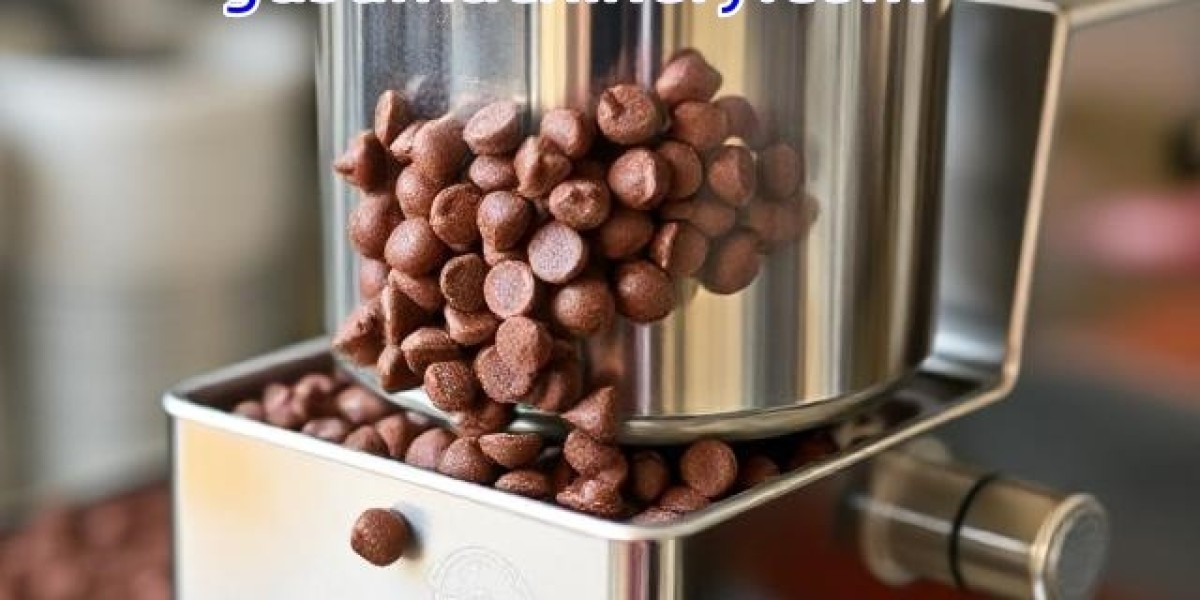

One key expectation is consistent chocolate refinement. Buyers look for machines capable of producing uniform particle size with minimal variations. Uniform chocolate flow enhances downstream processes like conching, molding, or enrobing. When a manufacturer ensures reliable refinement, production lines can operate continuously without frequent adjustments, reducing potential workflow interruptions.

Another important factor is machine adaptability. Chocolate formulations, ingredient types, and batch sizes often vary. Manufacturers that offer flexible machines, allowing easy adjustment of grinding speed, temperature, or feed rate, help factories maintain efficiency across different products. Buyers typically expect equipment that can adapt to these variations without causing downtime.

Maintenance and operational accessibility are also significant. Buyers anticipate that machines are designed for routine cleaning, inspection, and minor repairs without extensive disassembly. Equipment that supports predictable maintenance routines reduces unplanned stoppages and keeps production schedules steady, which is essential for high-volume operations.

Integration capabilities influence buyer expectations as well. Chocolate ball mills need to work smoothly with upstream ingredient feeders and downstream processing lines. Manufacturers that provide equipment designed for seamless connectivity help factories maintain a continuous chocolate flow. This ensures that refining, mixing, and molding processes remain synchronized and efficient.

Technical support and documentation are practical considerations. Buyers expect manufacturers to provide clear manuals, troubleshooting guidance, and operational recommendations. Well-supported machines allow production teams to handle minor issues quickly, reducing delays and enhancing overall workflow reliability.

Energy efficiency and temperature management are also evaluated. Chocolate ball mills that regulate heat effectively prevent product hardening and viscosity changes. Buyers appreciate solutions that minimize energy consumption while maintaining stable chocolate characteristics, contributing to smoother production performance.

Safety and compliance standards form another aspect of expectation. Machines that meet industry guidelines and food safety regulations help buyers avoid regulatory challenges. Reliable safety features, along with user-friendly operation, foster confidence in daily use and support consistent performance.

Within these considerations, Gusu focuses on providing chocolate ball mill solutions that align with practical production realities. The emphasis is on predictable operation, adaptable design, and reliable support rather than exaggerated performance claims. Buyers can expect equipment that improves efficiency while fitting seamlessly into existing production environments.

By emphasizing these practical factors, Gusu supports chocolate manufacturers seeking dependable, consistent chocolate refinement, helping factories maintain smooth and efficient workflows.

Detailed insights into chocolate ball mill machinery are available at https://www.gusumachinery.com/news/industry-news/what-is-a-chocolate-ball-mill-everything-you-need-to-know.html