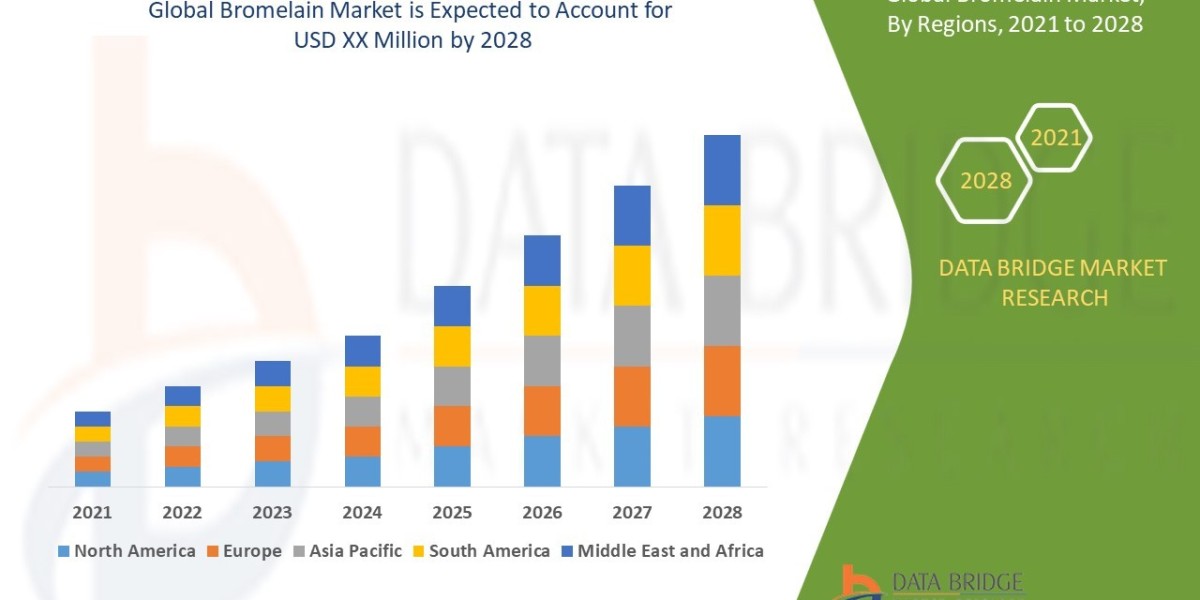

The global porous metal sheet market is entering a high-growth phase, supported by industrial reinvestment, clean-energy acceleration, and advanced filtration requirements across key manufacturing economies. According to the latest market outlook, the industry is valued at USD 653.4 million in 2025 and is projected to reach USD 1,159.1 million by 2035, expanding at a 5.9% CAGR—representing a USD 505.7 million absolute dollar opportunity over the decade.

With adoption intensifying in chemical processing, pharmaceuticals, hydrogen systems, aerospace, and next-generation battery platforms, the porous metal sheet market is expected to grow 1.77X between 2025 and 2035.

Industry Growth Driven by High-Performance Filtration & Clean Energy Expansion

Porous metal sheets are increasingly replacing polymer and ceramic alternatives due to their superior corrosion resistance, temperature tolerance, reusability, and mechanical strength. The market’s leading segment—filtration, with a 40% share in 2025—continues to anchor demand across petrochemicals, pharmaceuticals, water treatment, and power generation.

Subscribe for Year-Round Insights → Stay ahead with quarterly and annual data updates: https://www.futuremarketinsights.com/reports/sample/rep-gb-23312

Between 2025 and 2030, market value is forecast to rise from USD 653.4 million to USD 870.3 million, generating USD 216.9 million in new opportunities. This phase is expected to be shaped by:

- Strengthened regulatory compliance for particulate control

- Increased transition from polymer membranes to longer-life metal media

- Rapid adoption of structured metal meshes in catalytic and electrochemical systems

From 2030 to 2035, the industry is projected to add another USD 288.8 million, supported by advancements in:

- Hydrogen fuel cell plates and gas diffusion layers

- Lithium-ion and solid-state battery thermal barriers

- Biomedical implants and precision surgical components

- Waste heat recovery and high-temperature gas filtration

Technological Advancements Accelerate Adoption

Sintering, powder metallurgy, additive manufacturing, and multi-layer lamination are enabling:

- Custom pore sizes

- Gradient density structures

- Higher structural precision

- Enhanced permeability and flow uniformity

This technological capability supports manufacturers’ shift toward application-specific designs for energy systems, smart factories, aerospace engines, and contamination-controlled medical environments.

Material & Process Insights

Stainless Steel Leads with 48% Share (2025)

Stainless steel continues to dominate due to its:

- Excellent corrosion resistance

- High strength-to-weight ratio

- Compatibility with food, pharma, and high-heat filtration

Sintered Powder Sheets Hold 42% Manufacturing Share

Favored for their uniform porosity and cost-effective large-scale production, these sheets are widely used in:

- Industrial gas filtration

- Catalyst support structures

- Aerospace flow control components

Regional Growth Highlights

Europe: Market to Reach USD 212.6 Million by 2035 (3.6% CAGR)

Key trends include:

- Germany’s pivot toward electrolyzers and high-purity filtration

- Spain’s rising share due to industrial air treatment investments

- Italy’s expansion in stainless steel and medical-grade filter systems

United States: 4.7% CAGR Driven by Industrial Retrofitting

Demand growth is supported by:

- EPA-mandated filtration upgrades

- Increased biotech and sterile filtration applications

- Adoption of metal mesh for defense-grade noise suppression

- Domestic hydrogen supply chain localization

Saudi Arabia & Middle East: Clean-Tech Project Uptake Accelerates

Although not quantified in the dataset, regional adoption is rapidly rising due to:

- Investment in hydrogen and desalination plants

- Energy diversification and industrial modernization

- Rising use of metal-based filtration in oil & gas facilities

China: Fastest-Growing Market at 6.8% CAGR

Growth is powered by:

- Massive wastewater treatment programs

- Automotive pressure equalization systems

- Expanded local manufacturing for export-grade porous filters

Japan & South Korea: Technology-Driven Demand

- Japan’s filtration segment holds 37% share, led by medical devices, precision electronics, and acoustic damping

- South Korea’s stainless steel usage stands at 42%, supported by electronics, batteries, and hydrogen equipment manufacturing

Need tailored insights? Request report customization to match your specific business objectives: https://www.futuremarketinsights.com/customization-available/rep-gb-23312

Industry Drivers & Restraints

Key Growth Drivers

- High-performance filtration across chemicals, pharma, and energy

- Surge in hydrogen fuel cell and electrolyzer production

- Rising demand for corrosion-resistant, high-temperature materials

- Transition toward reusable and backflushable filtration systems

Market Restraints

- High production and engineering costs

- Limited global manufacturing capacity

- Price sensitivity in non-critical industrial applications

Top Market Trends

- Process-specific customization for OEM performance benchmarks

- Multi-layer sintered laminates for improved acoustic damping

- Increased use in battery cooling and thermal management systems

Competitive Landscape

Key players are investing in large-scale manufacturing, advanced alloys, and clean-energy component production. The market features leading companies such as:

- Mott Corporation

- Taisei Kogyo Co., Ltd.

- Van Borselen

- ShengzhenHengko

- Applied Porous Technologies

A major industry development includes Mott Corporation’s 2024 expansion, adding a 65,000 sq. ft. facility in Connecticut, aimed at producing next-generation porous metal components for hydrogen fuel cells and electrolyzers, creating 100 high-tech jobs.

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: Empowering Decisions that Drive Real-World Outcomes: https://www.futuremarketinsights.com/why-fmi